Page 65 - Research Report 2021 - Institut für Leichtbau und Kunststofftechnik

P. 65

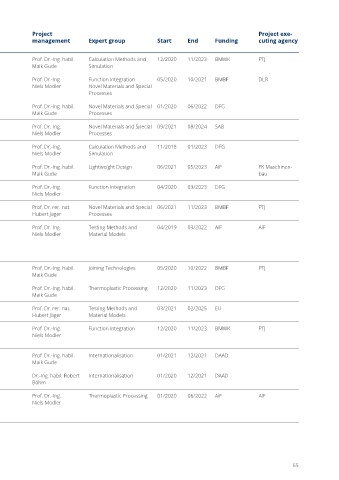

Project Project exe-

management Expert group Start End Funding cuting agency

GEPART Development of efficient process technologies within the closed particle foam material cycle Prof. Dr.-Ing. habil. Calculation Methods and 12/2020 11/2023 BMWK PTJ

SP: Virtual and experimental material characterisation for rEPP and EPP particle foam Maik Gude Simulation

GERUSAM Additive manufacturing technologies for functionalized lightweight structures Prof. Dr.-Ing. Function Integration 05/2020 10/2021 BMBF DLR

Niels Modler Novel Materials and Special

Processes

GESCHA II Investigation of the regularities of foam structure formation in freeze foaming processes of bio- Prof. Dr.-Ing. habil. Novel Materials and Special 01/2020 06/2022 DFG

compatible ceramic foams Maik Gude Processes

GRETA Generative production of recyclable basic structures for theatre sculpture from natural-based ma- Prof. Dr.-Ing. Novel Materials and Special 09/2021 08/2024 SAB

terials Niels Modler Processes

GRK 2430 Research Training Group 2430 Prof. Dr.-Ing. Calculation Methods and 11/2018 01/2023 DFG

I-FEV Interactive Fiber Rubber Composites Niels Modler Simulation

HORA High-performance radial impellers in modular metal-fibre composite design Prof. Dr.-Ing. habil. Lightweight Design 06/2021 05/2023 AiF FK Maschinen-

Maik Gude bau

HYBSCH Design development and technology synthesis for the production of cellular hybrid plastic struc- Prof. Dr.-Ing. Function Integration 04/2020 03/2023 DFG

tures for application in acoustic resonators Niels Modler

HYDRUN Boundary layer analysis for the inline hybridization of metal die casting and plastic injection molding Prof. Dr. rer. nat. Novel Materials and Special 06/2021 11/2023 BMBF PTJ

Hubert Jäger Processes

HYFOTOOL Hybrid Forming Tool - Development of an ultra-light, high-performance steel/plastic hybrid tool for Prof. Dr.-Ing. Testing Methods and 04/2019 03/2022 AiF AiF

deep-drawing sheet metal, including a first-time integration of RVDT sensor technology for record- Niels Modler Material Models

ing the tool stresses.

SP: Investigation of the material properties and development of the reinforcement structures for

the HyFo tool on the basis of FE simulations.

HYPRO Holistic implementation of hybrid design in series production Prof. Dr.-Ing. habil. Joining Technologies 05/2020 10/2022 BMBF PTJ

Maik Gude

HYSTERESIS Cyclic-dynamic properties of particle foams Prof. Dr.-Ing. habil. Thermoplastic Processing 12/2020 11/2023 DFG

Maik Gude

ICLIMABUILT Functional and advanced insulating and energy harvesting/storage materials across climate adap- Prof. Dr. rer. nat. Testing Methods and 03/2021 02/2025 EU

tive building envelopes Hubert Jäger Material Models

I-DETEKT Intelligent battery protection system for electric vehicles for detection of undesired mechanical Prof. Dr.-Ing. Function Integration 12/2020 11/2023 BMWK PTJ

damage Niels Modler

SP: Development e-Preform

ILK2PATRAS 1st Greek-German Summer School of University of Patras & TU Dresden Prof. Dr.-Ing. habil. Internationalisation 01/2021 12/2021 DAAD

Maik Gude

ILKINAUS Development of tailored carbon fibres for multifunctional composites Dr.-Ing. habil. Robert Internationalisation 01/2020 12/2021 DAAD

Böhm

IMEM Development of an innovative membrane press for the efficient manufacturing of fibre compos- Prof. Dr.-Ing. Thermoplastic Processing 01/2020 06/2022 AiF AiF

ite components made of thermoplastic semi-finished products in small and medium series sizes. Niels Modler

SP: Development of an optimised process control as well as a temperature management for the

efficient manufacturing of composite fibre components in the innovative membrane press

65

65