Page 78 - Research Report 2021 - Institut für Leichtbau und Kunststofftechnik

P. 78

Doctorates

Doctorate Dr.-Ing. Dustin Nielow

Effect of manufacturing-induced imperfections on the

fatigue behavior of composite sandwich shell structures

Supervising Professor: Prof. Dr.-Ing. habil. Maik Gude

The PhD thesis, with a focus on renewable energies, was specimen and condition monitoring as well as the vali-

developed as part of a sub-project of the joint project dated FEM model, makes it possible to examine the sub-

“BladeTester” (of the Federal Ministry of Economics and structures similar to the rotor blade shell under realistic

Climate Protection – BMWK, FKZ: 0325298A) and in close load scenarios without stability failure and to represent

cooperation between the Bundesanstalt für Material- their complex deformation behavior numerically. The in-

forschung und -prüfung (BAM) and the TU Dresden. In fluence of manufacturing-induced imperfections on dam-

detail, the following question was addressed: Wind tur- age initiation and the significant reduction of service life,

bines often exhibit cracks in the blade shells after only a as well as the design rules derived from this work, pro-

few years in service, significantly before their expected vide important design information for engineering prac-

20 to 30 year design lifespan. This leads to complicated tice and support the operationally safe design of curved

repairs on difficult to reach rotor blades, and can cause sandwich structures such as wind turbine rotor blades.

a cost-intensive stand-still of the turbine.

A possible source of these defects in the rotor blade

shells are the imperfections which occur during produc-

tion. In order to investigate the effect of these imper-

fections on the fatigue behavior of rotor blades, a test

rig was developed at the BAM upon which intermedi-

ate scale static and cyclic-fatigue testing could be per-

formed. The complementary sandwich shell specimens

developed and investigated with the test rig are repre-

sentative of the outer shell of wind turbine rotor blades

in terms of materials and manufacturing processes, as

well as structural mechanics. The specimens were built

with reproducible imperfections, including laminate over-

laps in the face sheets and gaps of varying size in the

foam core. The damage condition was monitored during

cyclic-fatigue testing under realistic load cases using a

combination of in-situ passive thermography and strain

field measurement.

© Dustin Nielow

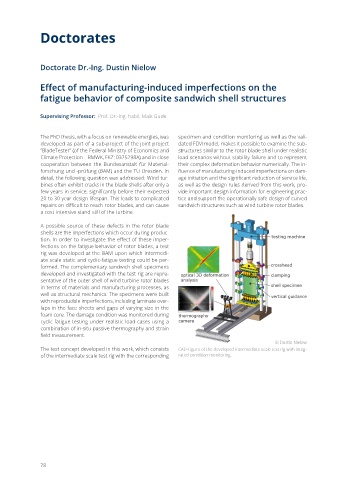

The test concept developed in this work, which consists CAD-Figure of the developed intermediate scale test rig with integ-

of the intermediate scale test rig with the corresponding rated condition monitoring.

78